008615129504491

|

Material |

Gr1, Gr2 |

|

Standard |

ASTM F67, IS05832-2 |

|

Regular Size |

0.6-1.0 T * (280~350) W * (1000~2000 )L mm |

|

Thickness tolerance |

0.05-0.1 mm |

|

State |

M (Annealed) |

|

Surface |

Cold-rolled surface |

|

Roughness |

Ra<0.08um |

Chemical composition:

|

Grade |

Ti |

Chemical composition | ||||||

|

Impurity(=<%) |

Residual elements |

|||||||

|

Fe |

C |

N |

H |

O |

Single |

Total |

||

|

Gr1 |

Bal |

0.20 |

0.08 |

0.03 |

0.015 |

0.18 |

0.10 |

0.40 |

|

Gr2 |

Bal |

0.30 |

0.08 |

0.03 |

0.015 |

0.25 |

0.10 |

0.40 |

Mechanical property:

|

Material |

Condition |

Thickness mm |

Mechanical Property |

||

|

Tensile strength Rm/Mpa |

Yield strength Rp0.2/Mpa |

Elongation A% |

|||

|

Gr1 |

M |

<25 |

Min 240 |

Min 170 Max 310 |

Min 24 |

|

Gr2 |

M |

<25 |

Min 345 |

Min 275 Max 450 |

Min 20 |

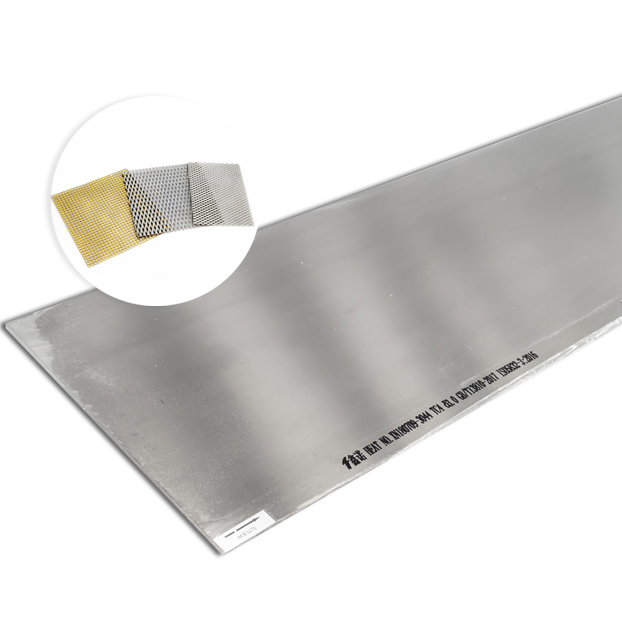

Being in the line of the titanium products manufacturer, our company produces titanium products which mainly direct to the medical fields. For the ASTM F67 Gr 1 titanium mesh plate for skull, it can be used to produce the titanium mesh implanted in skull. The Gr1-Gr2 titanim material has better extensibility than Gr3 and Gr4.

We adhere to quality policy of scientific management, quality first, continuous improvement and customer service. After ten years development, we have been the specialized R&D medical titanium and titanium alloy products’ first production base and the leader of China medical titanium material. With great vision, it has grown to be one of the most important medical titanium players.

Imported the ALD oven from German to melt titanium ingot. Use the 0 grade undersized grain titanium sponge. For the thick 0.5 to 1.0mm thickness sheets, the tolerance can reach 0-0.08mm. 100% ultrasonic/turbine flaw detection to eliminate metallurgical defects and non-ferrous impurities.

All these equipments and control can ensure the qualtiy of Gr 2 titanium mesh plate for skull. The precision tolerance control can save the raw material for customers.