008615129504491

|

Chemical compositions |

||||||||

|

Grade |

Ti |

Al |

V |

Fe, max |

C, max |

N, max |

H, max |

O, max |

|

Ti-6Al-4V ELI |

Bal |

5.5~6.5 |

3.5~4.5 |

0.25 |

0.08 |

0.05 |

0.012 |

0.13 |

|

Grade 5 (Ti-6Al-4V) |

Bal |

5.5~6.75 |

3.5~4.5 |

0.3 |

0.08 |

0.05 |

0.015 |

0.2 |

|

Mechanical properties |

|||||

|

Grade |

Condition |

Tensile Strength (Rm/Mpa) ≥ |

Yield Strength (Rp0.2/Mpa) ≥ |

Elongation (A%) ≥ |

Reduction of Area (Z%) ≥ |

|

Ti-6Al-4V ELI |

M |

860 |

795 |

10 |

25 |

|

Grade 5 (Ti-6Al-4V) |

M |

860 |

780 |

10 |

/ |

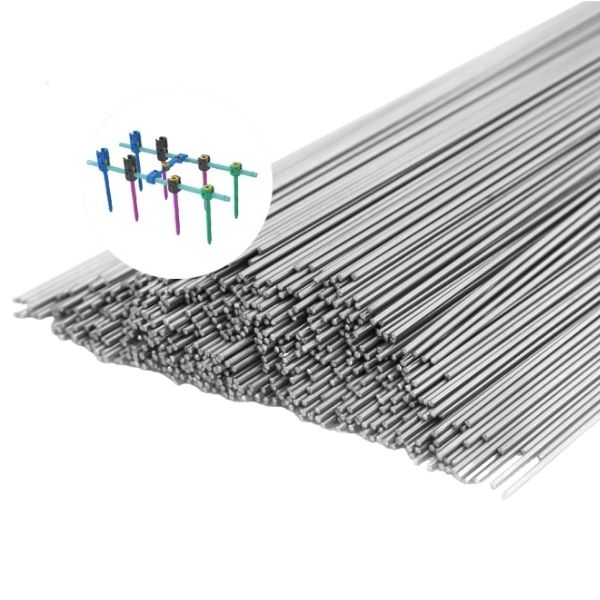

XINNUO produced Ti-6Al-4V ELI titanium bars’ microstructure can reach within A3 and Tensile Strength can reach more than 1100Mpa. Titanium bar for spine screws is used for spinal implants, the quality is very important.

1. Chemical compositions is determined by the used titanium sponge grade, XINNUO uses O grade undersized grain;

2. Microstructure is determined by the melting times, XINNUO melts 3 times by imported Germany ALD oven;

3. Mechanical properties is determined by the rolling and annealing processes, XINNUO controls every production step;

4. Inner defects and surface crack is determined by the quality check, XINNUO uses the Eddy current flaw detector and Ultrasonic flaw detector to test every bar;

5. Surface of XINNUO titanium bars is checked by the ODE optical surface detector combine the manual detection;

6. Tolerance of XINNUO titanium bars is checked by the Infra-ray diameter gauge.

All these processes lead to the final quality of the medical titanium bars and ensured the quality of XINNUO products.