Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Titanium Coil Wire, ISO 5832-11 Titanium sheet, F136 Titanium Bar, We will supply best quality, the most market competitive price, for every new and old customers with the most perfect green services.

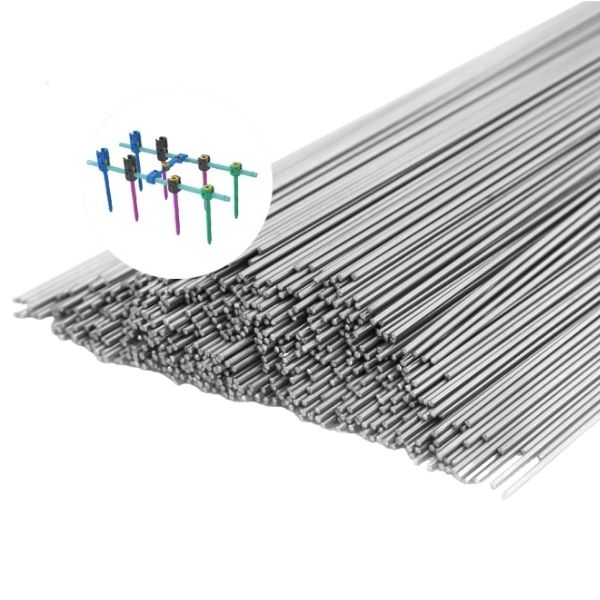

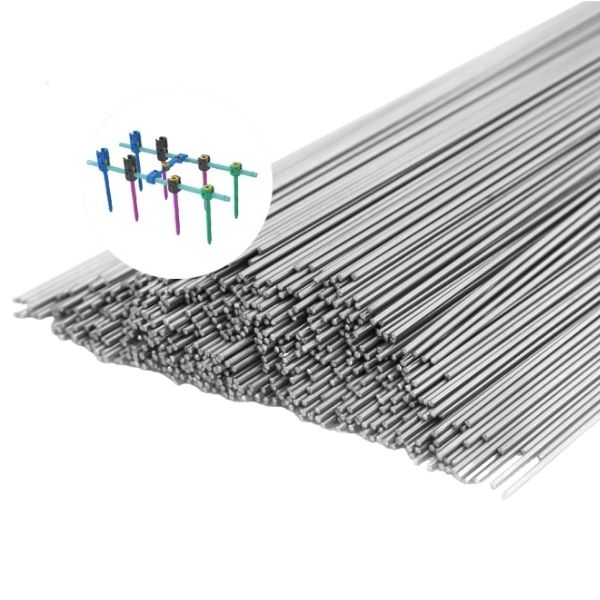

Quality Inspection for Titanium Bar Gr12 - Titanium bar for spine screws – Xinnuo Detail:

Specifications

|

Chemical compositions

|

|

Grade

|

Ti

|

Al

|

V

|

Fe,

max

|

C,

max

|

N,

max

|

H,

max

|

O,

max

|

|

Ti-6Al-4V ELI

|

Bal

|

5.5~6.5

|

3.5~4.5

|

0.25

|

0.08

|

0.05

|

0.012

|

0.13

|

|

Grade 5 (Ti-6Al-4V)

|

Bal

|

5.5~6.75

|

3.5~4.5

|

0.3

|

0.08

|

0.05

|

0.015

|

0.2

|

|

Mechanical properties

|

|

Grade

|

Condition

|

Tensile Strength (Rm/Mpa) ≥

|

Yield Strength (Rp0.2/Mpa)

≥

|

Elongation (A%)

≥

|

Reduction of Area (Z%)

≥

|

|

Ti-6Al-4V ELI

|

M

|

860

|

795

|

10

|

25

|

|

Grade 5 (Ti-6Al-4V)

|

M

|

860

|

780

|

10

|

/

|

XINNUO produced Ti-6Al-4V ELI titanium bars’ microstructure can reach within A3 and Tensile Strength can reach more than 1100Mpa. Titanium bar for spine screws is used for spinal implants, the quality is very important.

How XINNUO control the quality of medical titanium bars?

1. Chemical compositions is determined by the used titanium sponge grade, XINNUO uses O grade undersized grain;

2. Microstructure is determined by the melting times, XINNUO melts 3 times by imported Germany ALD oven;

3. Mechanical properties is determined by the rolling and annealing processes, XINNUO controls every production step;

4. Inner defects and surface crack is determined by the quality check, XINNUO uses the Eddy current flaw detector and Ultrasonic flaw detector to test every bar;

5. Surface of XINNUO titanium bars is checked by the ODE optical surface detector combine the manual detection;

6. Tolerance of XINNUO titanium bars is checked by the Infra-ray diameter gauge.

All these processes lead to the final quality of the medical titanium bars and ensured the quality of XINNUO products.

Product detail pictures:

Related Product Guide:

Our pursuit and company intention is usually to "Always fulfill our purchaser requirements". We go on to acquire and layout excellent high quality products for both our previous and new consumers and realize a win-win prospect for our customers too as us for Quality Inspection for Titanium Bar Gr12 - Titanium bar for spine screws – Xinnuo , The product will supply to all over the world, such as: Guatemala, Mauritius, Niger, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share the top trading practical experience with all our merchants.